main characteristics

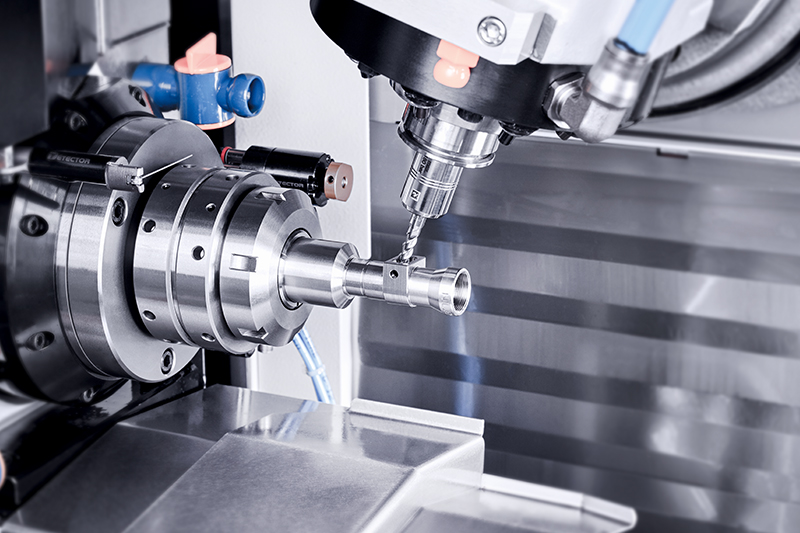

- 3-axis parallel kinematics, plus 1 rotational axis on the spindle

- Ultra-high-speed spindle, rotation up to 80,000 rpm

- Linear axis acceleration 10 m/s2 during machining

- Feed rate on linear axes X Y Z of 72 m/min

- Small footprint, approx 1 m2

DESCRIPTION

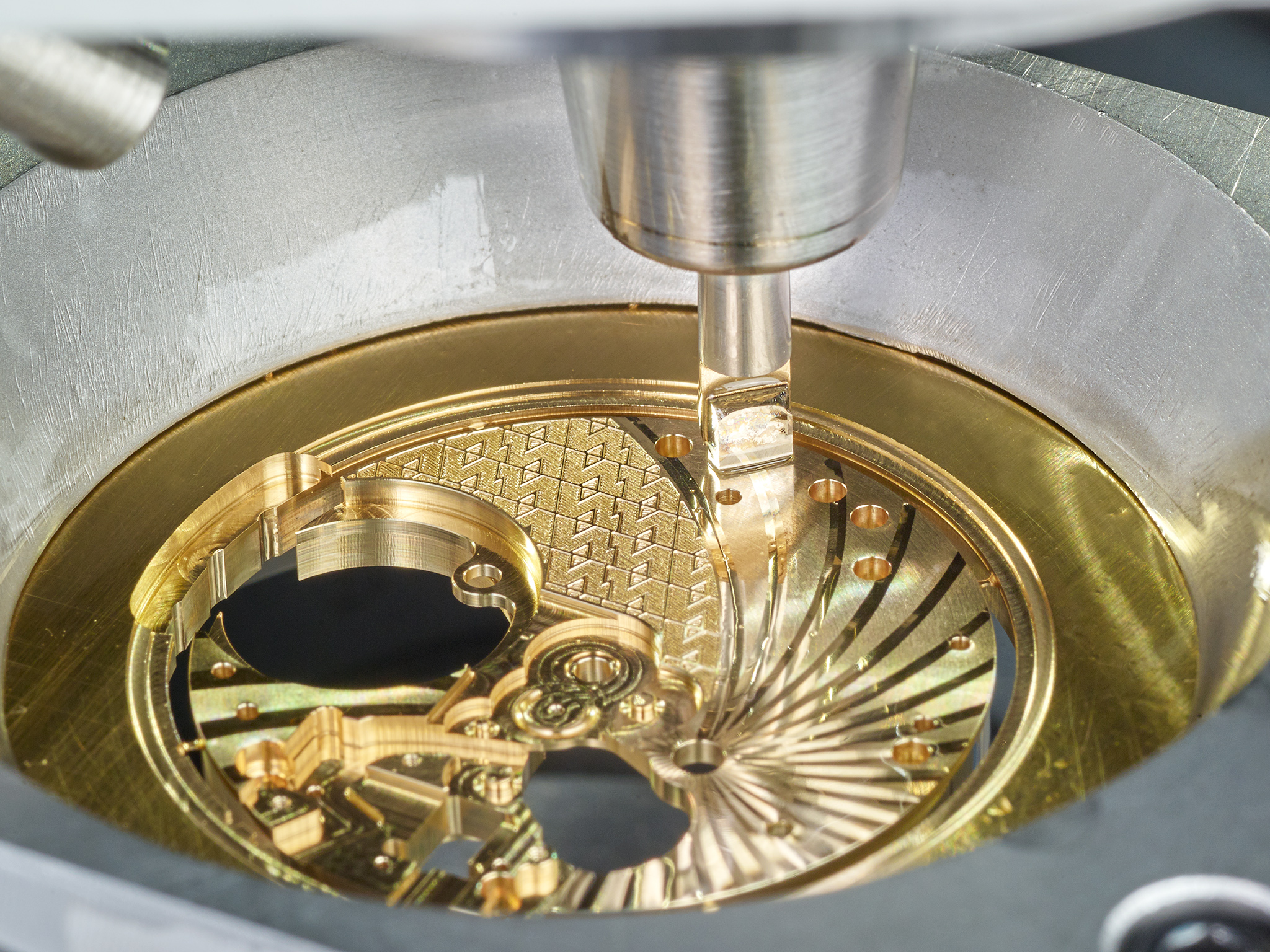

This new watchmaking kit machining concept – comprising one or more type 701S machines and an automation cell – speeds up production whilst reducing costs. Each center can contain up to five 701S machines supplied by a single robot.

The center itself can be configured with different options including a part cleaning device, multiple conditioning baskets, a vision recognition system, part sampling for statistical process control (SPC) and removal of non-compliant parts.

We can easily incorporate control equipment or add other options required for the production of watchmaking kits.

What makes this concept truly unique is the fact that each 701S machine in the "transfer" center is independent. Each machining center can be coordinated to operate with the other machining stations, or to work independently.

If one 701S machine in a production cell is being serviced, the production rate is limited, but production of each finished workpiece is still guaranteed.

-

Ultra-high-speed fixed spindle, 80,000 rpm

- Delta architecture, 3 articulated arms without play and without friction

- Ergonomically designed CNC with ISO programming and PC interface

- Detachable tool magazine with up to 72 positions

- Pallet magazine with 12 positions

- Swarf management with built-in filtration

solution finder

solution finder