308MT2

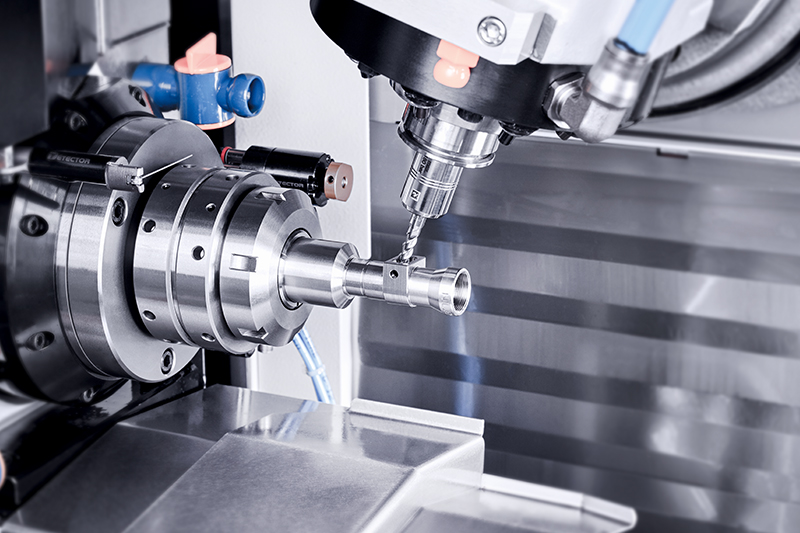

The 308MT2 is a multi-process machining center dedicated to machining complex parts from bar stock 3 mm to 30 mm in diameter. Highly compact, it benefits from the latest technological developments, with its ingenious design ensuring it offers first rate performances

- 5 to 7 axes

- Machining from bar stock

- Usinage

main characteristics

- Milling up to 60,000 rpm

- Powered spindle, from 0 - 40,000 rpm in 1.1 s

- Turning on the A axis up to 8000 rpm

- HSK-A32 interface

- Standard bar passage up to Ø 30 mm

- B axis angular movement -45° to +100°

DESCRIPTION

The 308MT2 is a multi-process machining center dedicated to machining complex parts from bar stock 3 mm to 30 mm in diameter. Highly compact, it benefits from the latest technological developments, with its ingenious design ensuring it offers first rate performances.

The kinematic chain has been optimized to guarantee a high degree of rigidity between the tip of the tool and the workpiece to be machined. The drives for the rotational axes with cooled torque motors ensure the machine benefits from a high level of thermal stability.

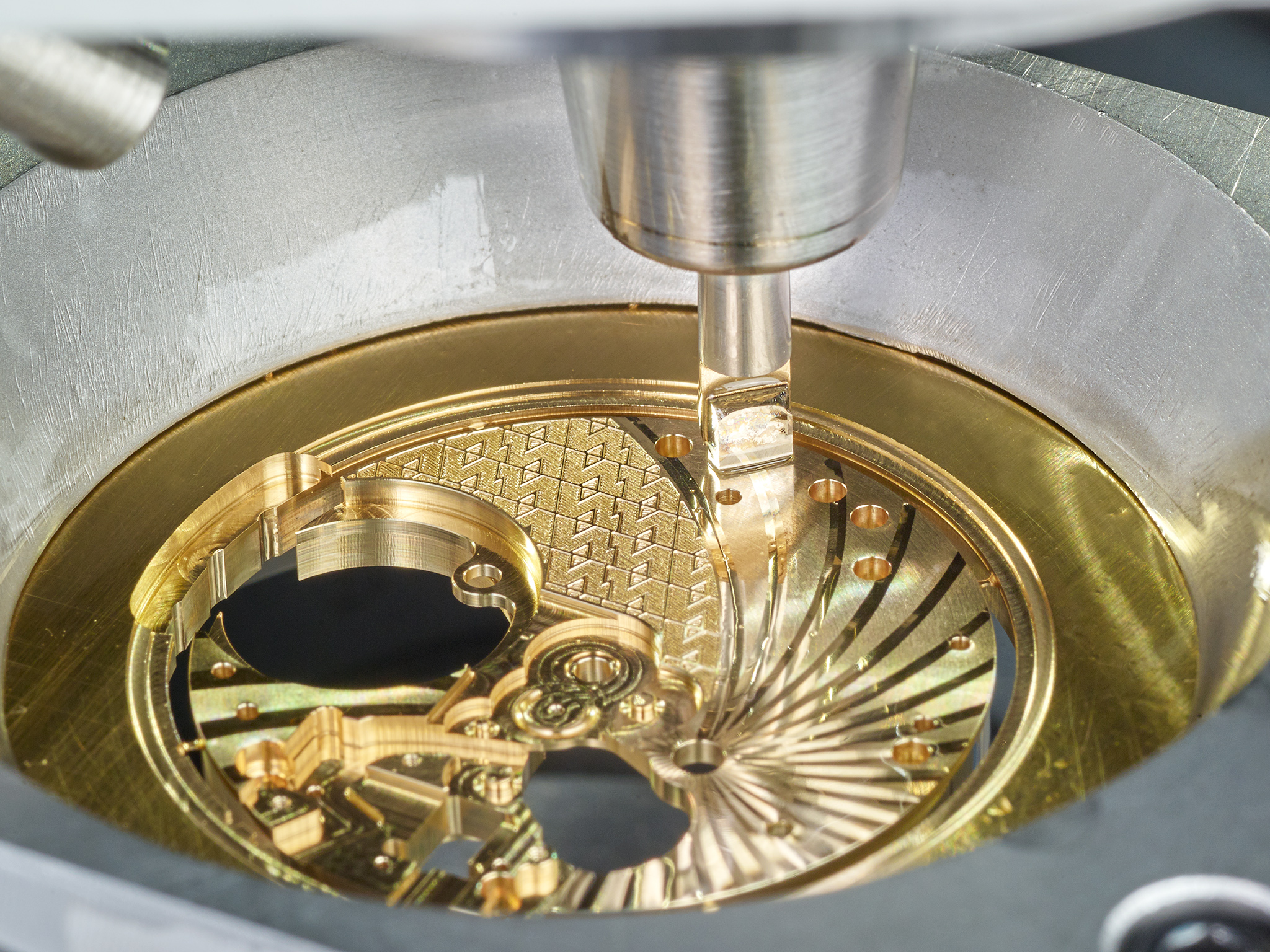

The high precision of the horizontal axis enables turning operations to be performed at up to 8000 rpm. The high-performance powered spindle offers maximum functionality, and enables milling at speeds of up to 60,000 rpm. The 308MT2 machining center can be equipped with a two-position simple and economical back machining unit which can accommodate a vice or even a collet for internal or external clamping. The back machining unit means complex parts can be machined in a single cycle. For greater autonomy, it can be coupled with a robotic cell which is perfectly integrated by Willemin-Macodel.

The guarantee that narrow tolerances and high surface finish requirements can be met are just two reasons why the 308MT2 machining center is the perfect solution for machining complex small parts for the most demanding, cutting-edge industries.

Other characteristics

- Milling up to 60,000 rpm

- Powered spindle, from 0 - 40,000 rpm in 1.1 s

- Turning on the A axis up to 8000 rpm

- HSK-A32 interface

- Standard bar passage up to Ø 30 mm

- B axis angular movement -45° to +100°

- B axis indexing from 0 ° - 90 ° in 0.2 sec

- High-precision measuring scale on the linear axes, resolution of 0.0001 mm

- Tool magazine with up to 28 positions

- Footprint approx 1.5 m2

- Powered spindle at 40,000 rpm with HSK-A32 interface (60,000 rpm milling as an option)

- A axis spindle/divider, turning up to 8000 rpm, max. bar through diameter Ø 30 mm

- Direct drive swiveling B axis, angular movement 145°

- Fanuc 31i-B5 NC with 10.4’’ screen fitted on a support independent of the machine

- 28-position pick-up type tool magazine with separate access door

- Two-position pickup unit 0° or 90° on the U axis, 135 mm travel

- Various automation/robotization systems, loading or unloading of workpieces or pallets (can be adapted on the right-hand side of the machine

- Swarf and cutting fluid recovery tray

solution finder

solution finder